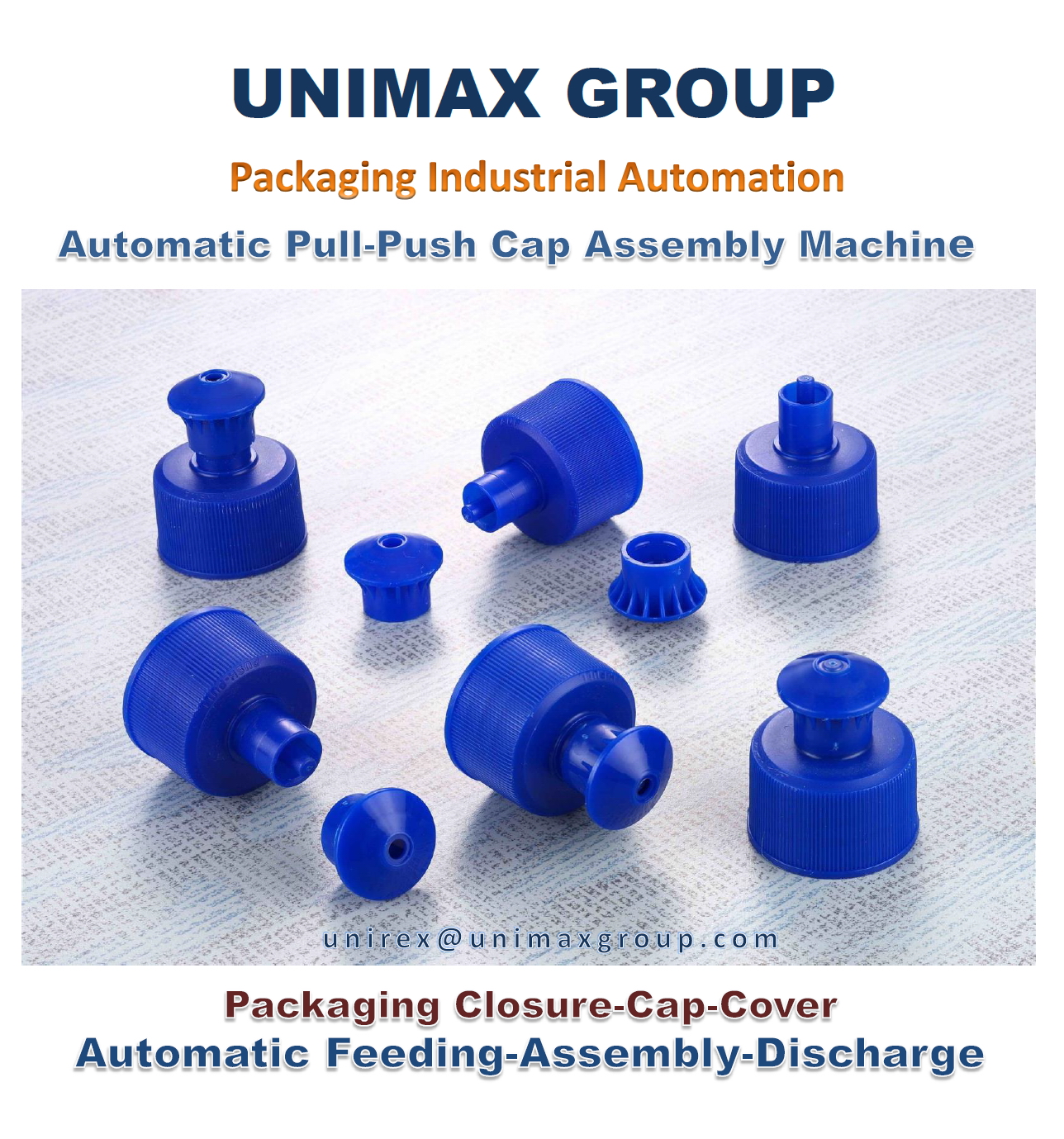

♦ Application:

• Pull-Push Cap with or without Outside Cap

• For Drinking Water, Shampoo, Liquid Detergent Bottle Cap, etc.

♦ Model:

• UAC-821-UL series without outside cap (1-Mold, 1-Cavity)

• UAC-831-UL series with outside cap (1-Mold, 1-Cavity)

• UAC-822-UL series without outside cap (1-Mold, 2-Cavity)

• UAC-832-UL series with outside cap (1-Mold, 2-Cavity)

» Specifications:

-

Parts arranging and feeding for nipple caps/nozzles

-

Unscrambler

-

Parts delivery

-

Parts arranging system

-

Parts track guiding system

-

Parts arranging and feeding for main caps

-

Unscrambler

-

Parts delivery

-

Parts arranging system

-

Parts track guiding system

-

Assembly system

-

Integrated programmable control(PLC) system

-

Sensor control system

-

Parts positioning device

-

Caps take-up system

-

Indexing disc, two-layer type

-

Multi-station system

-

Parts assembly system

-

Products discharging system

-

Optional

- Caps automatic feeding storage system

» Features:

-

For pull-push type of drinking water bottle cap assembly

-

Cap

-Cap with thread or pressure capping types

- Nipple cap as pull-push nozzle types

-

Separate parts automatic arranging and feeding with unscrambler system

-

No cap, no assembly

-

Rotary type of multi-station system

-

Cap parts position-setting system

-

Automatic parts of cap/nozzle assembly

-

Programmable logic control(PLC) system

-

Counter system

-

Automatic assembly caps discharge system

-

Improper assembly detecting system

|

相關商品

相關商品

(1).png)

.jpg)

.png)

相關商品

相關商品.jpg)

.jpg)