♦ Application:

• For PET/Plastic Thermoforming Clamcell / Carton / Box / Tray Labeling

• Automatic Peel-off Taking & Stacking Collecting System and

• Automatic Quantitative Stacking & Batch Collecting System

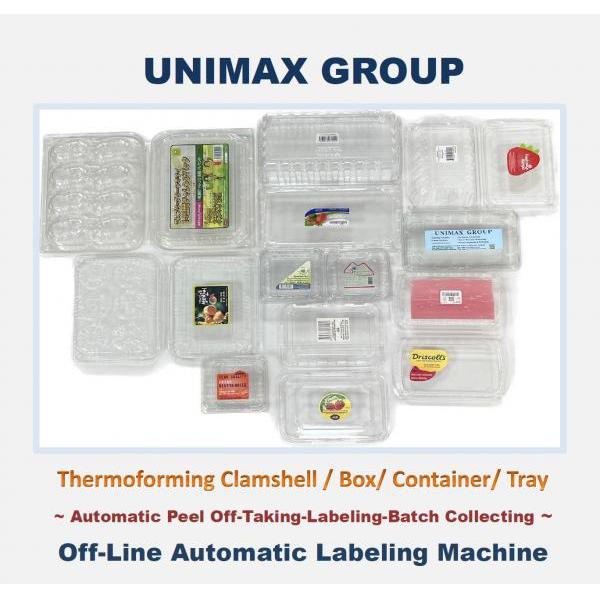

♦ Model:

• 311-VA-S2 Automatic Single-Labeling System

• 321-VA-S3 Automatic Twin-Labine System

* High Precision Servo Motor Control Labeling System.

» Specifications:

♦ Control System:

• Japan "Mitsubishi" PLC Control Sytem

• Inter-faced Colorful Touch Screen Monitor

• Conveyor with Japan Orient AC Motor Driving System

• With Italy Warm Gear Speed Reducer

• With Japan "YASKAWA" Servo Motor Labeling System

• Label Detecting Sensor: "Sick" Brand

♦ Specification:

• Product Size (Opened): Max. 330 (L) x 350/450 (W) mm (Formed & Trimmed)

• Labeling Accuracy: ± 2 mm

• Collector: 300 mm in Height

• Conveyor Feeding Speed: Approx. 30 m/min

• Operation Speed: Approx. 6~18 m/min

• Reference Capacity: Approx. 30~40 pcs/min Depend o Substances and Specification

• Product Size (Opened): Max. 330 (L) x 350/450 (W) mm (Formed & Trimmed)

♦ Optional:

- Transparent Label Sensor System

- NonAir Bubble Labeling Mechanism - For More Rigid Substances and Transparent Label

» Features:

♦ Features:

• For Products Top Labeling by Self-Adhesive Label

• Computerized Labeing Mechanism , No Scrash on Label & substances

• Servo Motor Control Pressure Sensitive Labeling System

• Nontransparent Type of Label

* Easy to Change Labeling and Conveyor Speed

• Easy to Adjust and Control Conveyor with Labeling Synchronously

• Labeling and Counting Synchronously

• Easy to Re-Load Label Roll while Running Out the Labels

* Short Time Needed only for Replacing Label Roll Hence Save Time to Stop Machine

• Automatic Box / Tray Take-Off with Stacking Collector (Servo Motor Control system)

• Adjustable Control for Labeling System (Labeling Position/ Height / Angle)

* The brand names of products shown in the catalogue are the reference application to our manufacturing equipment only.

|

相關商品

相關商品

相關商品

相關商品.jpg)

.jpg)

(1).png)

.jpg)

.png)

.jpg)