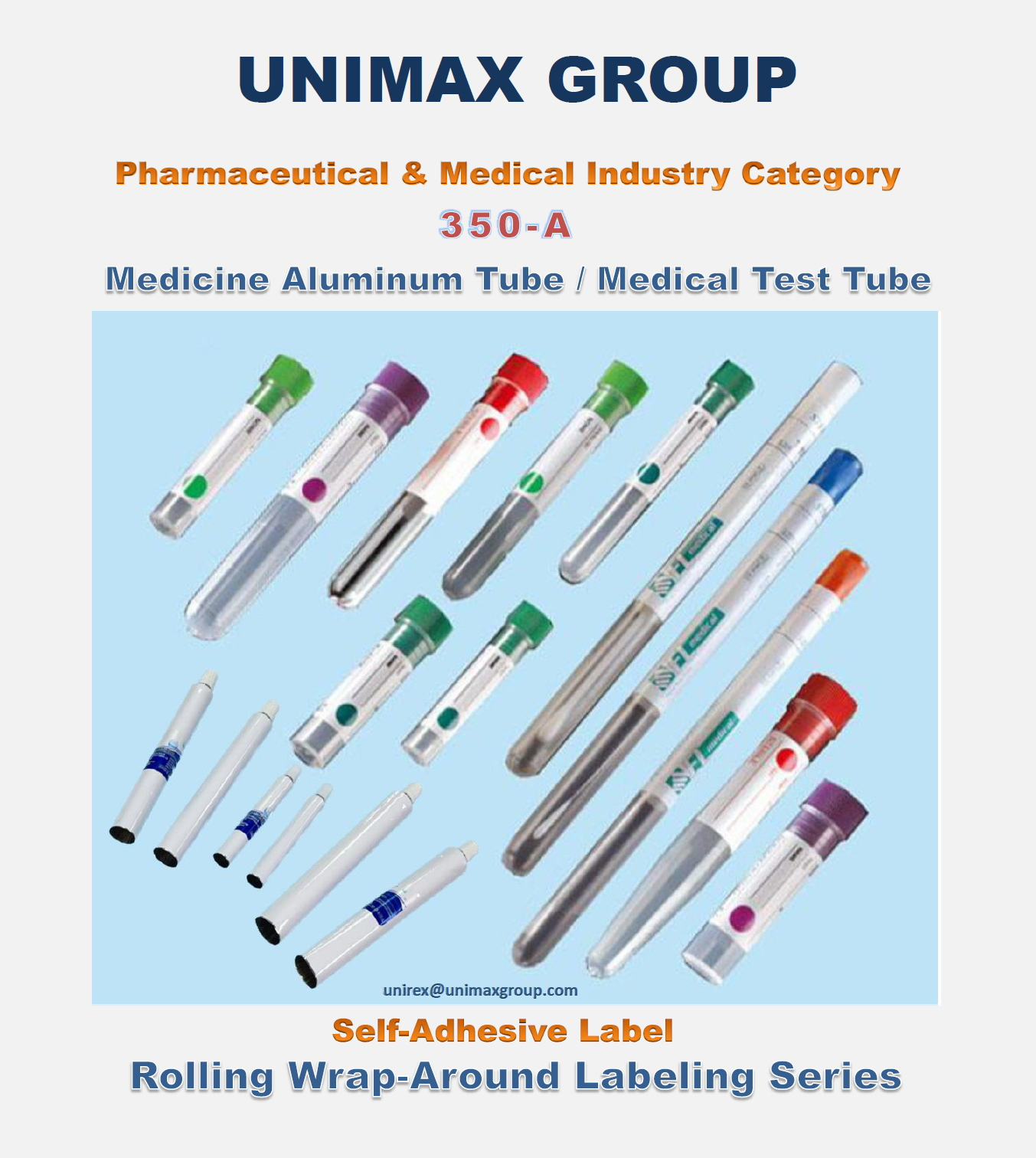

■ Pharmaceutical Aluminum / Medical Test Tube Rolling Wrap-Around Labeling Machine 350A

|

相關商品

相關商品

-

Pharmaceutical Industrial Products Labeling Machine

-

Automatic Punching-Filling-Capping Machine for Glucose Test Strips Vial

Automatic Punching-Filling-Capping Machine for Glucose Test Strips Vial

-

Glucose Test Strips Vial Labeling Machine for Wrap-Around & Security Strip Label with IC Chip

Glucose Test Strip Vial Wrap-Around & Security Strip Label with IC Chip Labeling

-

Glucose Test Strips Vial Wrap-Around Labeling Machine

Glucose Test Strips Vial Wrap-Around Labeling Machine

-

Glucose Test Strips Vial Wrap-Around with Tamper Proof Label Top & Corner Labeling Machine

Glucose Test Strips Vial Wrap-Around with Tamper Proof Label Top & Corner Labeling Machine

-

Glucose Test Strip Vial Top Labeling Machine with Tamper Proof Label ㄇ-Shape Seal Labeling System

Glucose Test Strip Vial Top Labeling Machine with Tamper Proof Label ㄇ-Shape Seal Labeling System

-

Glucose Test Strips Vial Compound Type Labeling Machine with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

Glucose Test Strips Vial Compound Type Labeling Machine -Equipped with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

-

Glucose Test Strips Vial Compound Type Labeling Machine with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

Glucose Test Strips Vial Compound Type Labeling Machine with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

-

Rolling Wrap-Around Labeling Machine for Pharmaceutical Vial with Peaked Cap

Rolling Wrap-Around Labeling Machine for Pharmaceutical Vial with Peaked Cap

-

Rolling Wrap-Around Labeling Machine for Medical Test Tube

-

Needle Cap Cylindrical Wrap-Around Labeling Machine

Needle Cap Cylindrical Wrap-Around Labeling Machine

-

U-Shape Wrap-Seal Labeling Machine for Biochemical Test Reagent Security Label

U-Shape Wrap-Seal Labeling Machine for Biochemical Test Reagent Security Label

(1).png)

.jpg)

.png)

.jpg)