Products

-

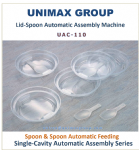

Automatic Lid-Spoon Assembly Machine

♦ Automatic Lid-Spoon Assembly Machine • For Food Products Packing Lid-Spoon Assembly • Lid & Spoon Automatic Feeding-Assembly-Collecting • No Need to Stop the Machine - For Supplementary Filling Lid & Spoon

-

.jpg)

Egg Box / Carton / Tray Labeling Machines (161)

Paper Pulp & Plastic Thermoforming Egg Carton Labeling Machine

-

.jpg)

EGMIR-68 Paper Pulp Egg Carton Servo Control Labeling Machine with Automatic Feeding -Collecting

Multi-Axis Servo Control X-Table Robot Twin-Labeling with Indexing Disc & Mold-Sets

-

.jpg)

EGMFRC-66 Paper Pulp Egg Carton Labeling Machine with X-Table Robot Automatic Feeding-Labeling-Batch Collecting System

4-Stack-Hopper Servo Control X-Table Robot Automatic Taking-Feeding-Labeling-Collecting System

-

EGMFRC-68 Paper Pulp Egg Carton Multi-Axis X-Table Robot Labeling Machine

• Automatic Output Conveyor Discharge Type • 4 Stack-Hopper Magazine Automatic Feeding System • X-Table Robot Automatic Labeling System

-

.jpg)

EGSCLP-68 / EGDCLP-68 Multi-Axis Servo Control Robot Paper Pulp Egg Carton Automatic Labeling Machine

Multi-Axis X-Table Robot Single/Twin-Labeling Machine for Paper Pulp Egg Carton

-

.jpg)

EGVAC-68 Multi-Application Paper Pulp Egg Carton Labeling Machine

Multi-Application Paper Pulp Egg Carton Labeling Machine with Multi-Axis Servo Control X-Table Robot Labeling System

-

.jpg)

EGSCLP-66 Automatic Paper Pulp Egg Carton Labeling Machine

Automatic Peeling Off-Feeding-Labeling-Discharge with Quantitative Collecting System

-

EGMI-66 Paper Pulp Egg Carton Labeling Machine

Indexing Disc with Mold-Sets Compact Type Automatic Paper Egg Carton Labeling Machine

-

EGMRR-66 Paper Pulp Egg Carton X-Table Robot Labeling Machine with Automatic Feeding-Collecting X-Table Robot System

Paper Pulp Egg Carton Labeling Machine with Automatic Feeding-Labeling-Collecting Servo Control X-Table Robot System

-

Paper Egg Carton / Box / Tray Automatic Labeling Machine

-

.jpg)

Pressure-Sensitive Automatic Labeling Machine for Paper Pulp/PET/Plastic Vacuum/Thermoforming Egg Carton/Box/Tray with Automatic Feeding and Collecting System

-

.jpg)

Thermoforming Egg Carton/Box Automatic Labeling Machine with Automatic Feeding-Quantitative Separation-Batch Collecting

Automatic Peeling Off-Feeding-Quantitative Separation-Batch Collecting System

-

PET/Plastic Thermoforming Egg Carton/Box Automatic Labeling Machine with Automatic Feeding & Collecting

Automatic Peeling Off-Feeding-Continuous Discharge

-

High Speed Labeling Machine with Automatic Feeding Quantitative Separation & Batch Collecting

Automatic Feeding Quantitative Separation & Batch Collecting

-

High Speed Automatic Labeling Machine for PET/Plastic Thermoforming Egg Carton/Box/Tray

■ Multi-application for Thermoforming Egg Carton/Box/Tray Lid ■ Automatic Robot Taking-off, Labeling, Quantitative Separation & Batch Collecting

-

.jpg)

Hot-melt Glue Thermoforming Egg Carton/Box/Clamshell Automatic Labeling Machine

Hot-melt Glue with General Precut Paper Label Plastic Egg carton Roller Gluing Labeling System

-

.jpg)

Automatic Labeling Machine for PET/Plastic Vacuum/Thermoforming Egg Carton/Box/Tray

Simple & Economic Type

-

High Speed Padding Machine for PET/Plastic Thermoforming Box/Tray/Container Absorbent Pad Sticking

High Speed 4-Jaw Robot Taking System & In-roll Type of Pad

-

.jpg)

High Speed PET/Plastic Thermoforming Tray / Carton / Box Labeling Machine with Four Labeling-Head

■ High Speed Robot Arm Taking System ■ Four-Labeling Head System

-

PET/Plastic Thermoforming Products Automatic Labeling Machine with Automatic Feeding & Continuous Discharge System

■ Automatic Feeding-Labeling System ■ Continuous Discharge & Collecting System

-

PET/Plastic Thermoforming Products Labeling Machine with Automatic Stacking-Collecting System

■ PET/Plastic Thermoforming Clamshell / Carton / Box / Tray ■ Automatic Feeding-Labeling-Quantitative Stacking Collection System

-

.jpg)

PET/Plastic Vacuum/Thermoforming Products Automatic In-Line Bottom / Top Labeling Machine

■ In-line Labeling System Combined with Thermoforming Line ■ Top or Bottom Labeling System

-

.jpg)

Self-Adhesive and Glue Applying Labeling Category

-

Pharmaceutical Industrial Products Labeling Machine

-

Glucose Test Strips Vial Labeling Machine for Wrap-Around & Security Strip Label with IC Chip

Glucose Test Strip Vial Wrap-Around & Security Strip Label with IC Chip Labeling

-

Glucose Test Strips Vial Wrap-Around Labeling Machine

Glucose Test Strips Vial Wrap-Around Labeling Machine

-

Glucose Test Strips Vial Wrap-Around with Tamper Proof Label Top & Corner Labeling Machine

Glucose Test Strips Vial Wrap-Around with Tamper Proof Label Top & Corner Labeling Machine

-

Glucose Test Strip Vial Top Labeling Machine with Tamper Proof Label ㄇ-Shape Seal Labeling System

Glucose Test Strip Vial Top Labeling Machine with Tamper Proof Label ㄇ-Shape Seal Labeling System

-

Glucose Test Strips Vial Compound Type Labeling Machine with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

Glucose Test Strips Vial Compound Type Labeling Machine -Equipped with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

-

Glucose Test Strips Vial Compound Type Labeling Machine with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

Glucose Test Strips Vial Compound Type Labeling Machine with Position Setting Wrap-Around & Tamper Proof Seal Labeling System

-

Rolling Wrap-Around Labeling Machine for Pharmaceutical Vial with Peaked Cap

Rolling Wrap-Around Labeling Machine for Pharmaceutical Vial with Peaked Cap

-

Rolling Wrap-Around Labeling Machine for Pharmaceutical Aluminum / Medical Test Tube

Pharmaceutical Aluminum / Medical Test Tube Rolling Wrap-Around Labeling Machine

-

Rolling Wrap-Around Labeling Machine for Medical Test Tube

-

Needle Cap Cylindrical Wrap-Around Labeling Machine

Needle Cap Cylindrical Wrap-Around Labeling Machine

-

U-Shape Wrap-Seal Labeling Machine for Biochemical Test Reagent Security Label

U-Shape Wrap-Seal Labeling Machine for Biochemical Test Reagent Security Label

-

Multi-Pieces Top Labeling Machine for Pregnancy Test Strip

Multi-Pieces Top Labeling Machine for Pregnancy Test Strip

-

Automatic Labeling - Assembly Machine for Hospital Wrist Band

Automatic Labeling - Assembly Machine for Hospital Wrist Band

-

Automatic Punching-Filling-Capping Machine for Glucose Test Strips Vial

Automatic Punching-Filling-Capping Machine for Glucose Test Strips Vial

-

Cosmetic Industry Labeling Series

Labeling, Assembly & Packaging Series for Cosmetic Industry

-

Cosmetic Plastic Box Double-Side Labeling with Paper Board Adhering Machine

Cosmetic Plastic Box Double-Side Labeling with Paper Board Adhering Machine

-

.jpg)

Single / Double-Side Labeling Machine with Corner L-Shape Seal Labeling System for Barcod or Security Label

-

Square Box 4-Side Wrap-Around Top Labeling Machine for Cotton Bud Box Top-Side-Bottom Wrap-Around Labeling

Square Box 4-Side Wrap-Around Top Labeling Machine for Top-Side-Bottom Wrap-Around Labeling Machine

-

Top & Wrap-Around Labeling Machine for Oval Shape Vial with Position Setting System

Top & Wrap-Around Labeling Machine for Oval Shape Vial with Position Setting System

-

High-Tech Industry Labeling Machine

High-Tech Industry Labeling & Processing Machine Series

-

High-Tech Products Labeling / Protection Film Adhering Series 310A for Soft and Rigid Cards

High-Tech Products Protection Film Labeling-Adhering Series for Soft and Rigid Cards

-

High-Tech Products Labeling Machine for Lens Industry and Protection Film Automatic Adhering

High-Tech Products Labeling Machine for Lens Industry and Protection Film Automatic Adhering

-

High-Tech Series for Lead Frames, Metals, Sheets High Precision Labeling

High-Tech Series for Lead Frames, Metals, Sheets High Precision Labeling

-

Multi-Pieces High Precision Labeling Series 310C3 for Memory Cards and Metal Sheets

Multi-Pieces High Precision Labeling Series 310C3 for Memory Cards and Metal Sheets

-

High-Tech Industry Application Series for Single Rigid Cards High Precision Labeling Machine

High-Tech Industry Application Series for Single Rigid Cards High Precision Labeling Machine

-

High-Tech Touch Panel, Lens, Cellular Phone Industries High Precision Labeling Machine

High-Tech Touch Panel, Lens, Cellular Phone Industries Precision Labeling Machine

-

Adhesive Applying Type Labeling Machine

Cold or Hot-melt Glue Applying Type Labeling Machines

-

Glue Applying Type Standard Labeling Machine

Glue Applying Type Standard 66-Series

-

Automatic Feeding Type 66 / 66L / 66LL-AF Labeling Machine

Glue Applying Automatic Feeding Type

-

Indexing Automatic Feeding Type Labeling Machine

Indexing Automatic Feeding Type Labeling Machine

-

Indexing Automatic Feeding Type Labeling Machine

Indexing Automatic Feeding Type Labeling Machine

-

Indexing Automatic Feeding Type Labeling Machine

Indexing Automatic Feeding Type Labeling Machine

-

Automatic Feeding with Conveyor & Mold-Sets Labeling Machine

Automatic Feeding with Conveyor & Mold-Sets Labeling Machine

-

Oval Shape Automatic Feeding Type Labeling Machine

Oval Shape Automatic Feeding Type Labeling Machine

-

.jpg)

Automatic Feeding Type Hot-melt Glue Labeling Machine

Automatic Feeding Type Hot-melt Glue Labeling Machine

-

Self-Adhesive Labeling Machine Series

-

Single / Double Side Labeling Machine

-

Cylindrical Bottle Wrap-Around Labeling Machine

-

Rolling Wrap-Around Labeling Machine

-

Automatic Table Type Top Labeling Machine

-

Automatic Table Type Cylindrical Substance Labeling Machine

-

Top Labeling Series

-

Corner Labeling Machine

-

Corner Labeling Machine for Flat Box

-

Flat Square Products Wrap-Around Labeling Machine

-

Automatic Labeling Machine for Plastic Bags

-

Plug-Liner-Cap Assy-Index-小圖(1).jpg)

UAC-820-CPL-D 5-Gallon Cap-Liner-Plug Automatic Assembly Machine

-

UAC-842-CPL-C 5-Gallon Cap-Liner-Plug Automatic Assembly Machine

-

Automatic Top Labeling Machine for Cap Seal Labeling

-

.jpg)

Assembly-Lining Machines

-

.jpg)

UAC-366-OC Automatic Cap & O-Ring Assembly Machine

-

Disc Cap Assembly Machine

-

Pull-Push Cap Assembly Machine

-

.jpg)

Flip-Top Cap Assembly Machine

-

.jpg)

Cap-Liner Assembly Machine

-

Automatic Lining Machine for Big-Deep Cover with Paper Board Liner

-

Automatic Lining Machine for Cosmetic Cap with EPE Liner

-

.jpg)

UAC-731-TC Automatic Cap-Spout Assembly-Lining Machine

-

Oil Cap Twist Assembly Machine

-

Lid-Spoon Assembly Machine

-

Multi-Purpose Pillow Type Mini Wrapping Machine

All commodities with adequate size can adopted by this multi-purpose series of machine, except those can not stand for hot-sealing, whatever candies, chocolate bar, chewing gums, biscuits, medicine, soaps, ice-bar, ice-pop, facial paper, wet wipes, dry cell, cutlery, panned goods; whatever its shape is square, rectangle, bar, or round, etc.

(1).png)

.jpg)

.png)